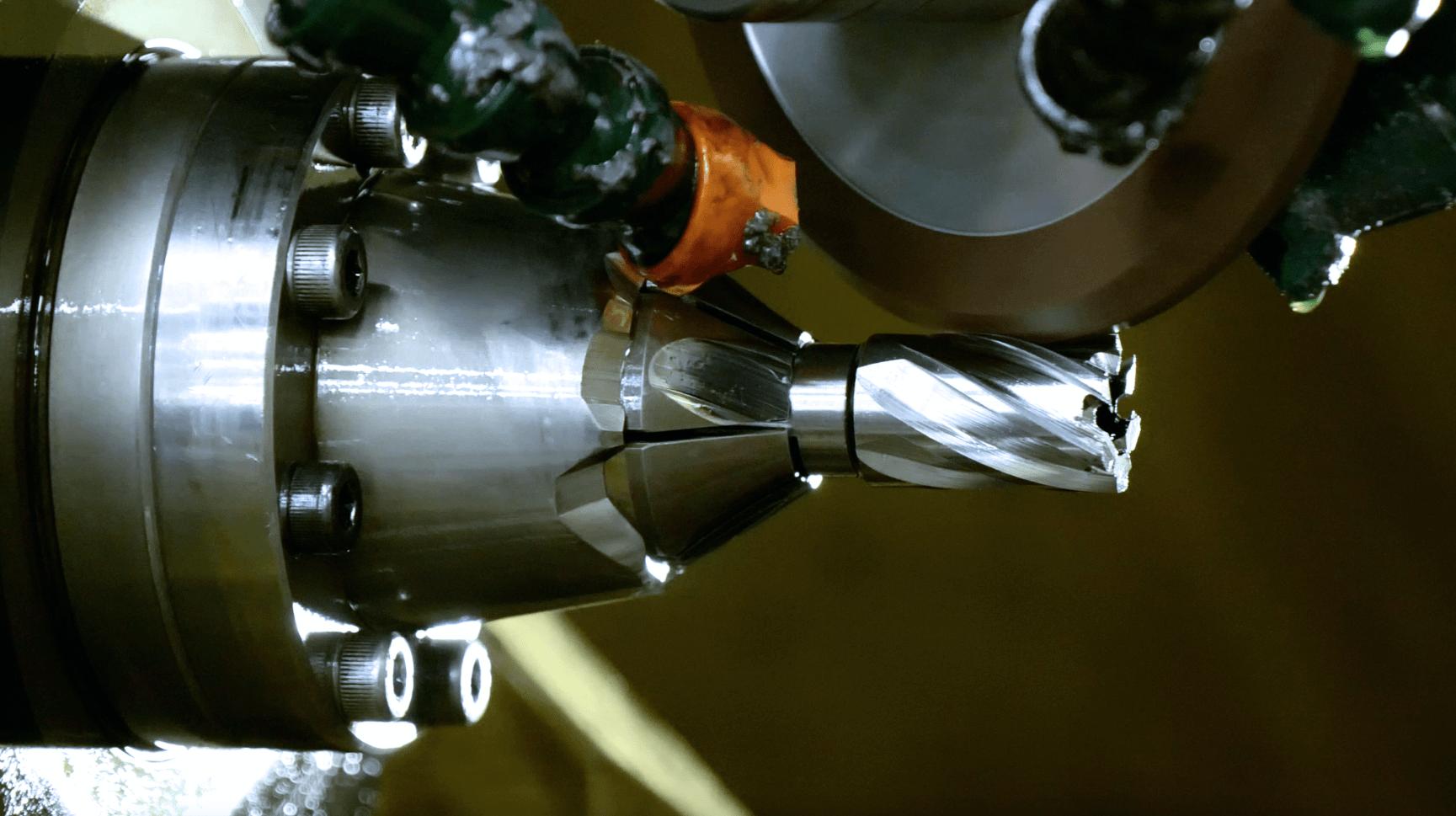

For over 20 years Bradford Tool Group have been manufacturing Supercut Rotabors also known as annular cutters or broaching cutters. The unique patented ‘CHIPBREAKER’ form, which we have designed and developed, allows faster swarf removal and gives longer tool life.

We are a leading supplier of top quality annular cutters & broaching cutters for both small & large international companies throughout the UK & worldwide.

Get In Touch

No other annular cutters or broaching cutters on the market will out-perform our tough Supercut Rotabors.

Why not contact us today for suppliers who can offer top quality cost effective annular cutting tools & broaching cutters fast, UK wide.

Quality Assurance